10 Sep Welcome to the Veraspec Newsletter – September 2019

Welcome to the Veraspec newsletter.

During the past couple of months, we have had the privilege to visit a number of Building Managers, Facilities Managers and Body Corporate committee members throughout the Gold Coast region.

Balcony balustrades; was a topic of much interest. I wish to share the following information, though it may not relate to all buildings it makes for interesting reading.

All balustrades glazing must be made from Grade A safety glass. If used at higher levels Grade A laminated safety glass should be considered due to its breakage characteristics.

The principal function of the AS/NZS – Australian and New Zealand Standard 1288, primarily a construction standard, is to enable the general public to be provided with safe glass products.

We are noticing with certain glass suppliers they will no longer supply the AS/NZS 2208 – Grade A – Heat Soaked – Toughen Glass – Heat Strengthen – 12mm to be used as balustrades. This type of balustrade glass may not be the safest option as this is only toughen and heat-soaked glass and not laminated, and in the event, it breaks it will just shatter into tiny pieces and you may no longer have a glass barrier held in place. The 13.52mm Clear toughened heat-soaked laminate glass is a preferred option (subject to engineer’s report) to be used as glass balustrades due to its added safety capabilities. In the event this glass was to break the laminate will hold the glass in tacked.

It is important for Building Managers and Body Corporate committees to take all steps necessary to provide the best possible outcome and Duty of Care. The question to ask is, are we looking at the best possible outcome towards the safety of both owners and the public interest. What would be the consequences if for example the balustrade glass was to break using non laminated glass?

Canada will only accept laminated glass balustrades in an attempt to increase the safety after the glass breaks. Single pane monolithic is outlawed. USA are looking to follow.

Toughened, or tempered glass is a type of high strengthened glass, formed by heating glass to the softening point (approx. 600° – 700° C) in a horizontal tempering furnace, then quickly cooling it by blasting the glass with cold air. This alters the surface tension of the glass, effectively ‘hardening’ the glass. Toughened glass is 4-5 times stronger than annealed glass of the same thickness. Due to the tension in the glass, toughened glass shatters into tiny cuboid fragments when broken, reducing the risk of injury. This quality determines toughened glass as a Grade A Safety Glass.

Heat Soak is a process that may expose impurities such as Nickel Sulfate – NiS inclusions in tempered glass. The process involves placing the tempered glass inside a chamber and raising the temperature to approximately 650°F to accelerate NiS expansion. This causes glass containing NiS inclusions to break in the heat soak chamber, thus reducing the risk of potential field breakage.

Benefits: Reduces potential public liability and low cost compared to glass replacement costs.

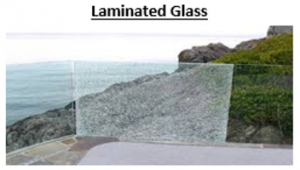

By using the combination of heat and extreme air pressure, laminated glass is produced by bonding two sheets of glass together with an  interlayer. PVB (polyvinyl butyral) is the most commonly used for the manufacture of laminated glass. Due to the interlayer, laminated glass remains in one piece when broken. This important quality determines laminated glass as a Grade A Safety Glass. Upon impact, the glass may break, however, will remain as one piece inside the frame. Laminated glass significantly reduces the risk of injury.

interlayer. PVB (polyvinyl butyral) is the most commonly used for the manufacture of laminated glass. Due to the interlayer, laminated glass remains in one piece when broken. This important quality determines laminated glass as a Grade A Safety Glass. Upon impact, the glass may break, however, will remain as one piece inside the frame. Laminated glass significantly reduces the risk of injury.

Note that Veraspec can provide to your building either glass or aluminium balustrades.

If you have any questions, our professional team are happy to assist.

Feel free to contact us anytime.